- Home

- Gear units

- Parallel Gearboxes

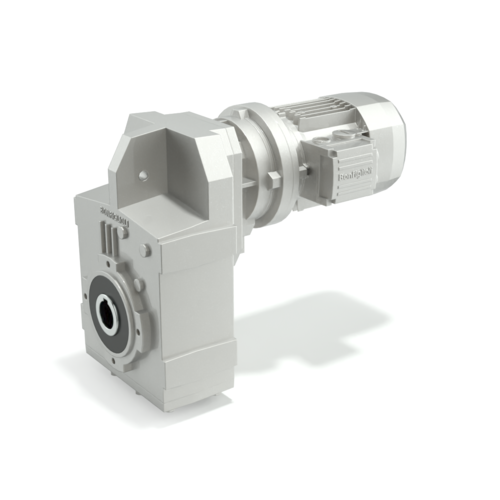

- Baureihe F

Die Baureihe F ist eine ausgezeichnete Lösung für Kunden, die einen Antrieb mit höchster Montageflexibilität benötigen. Dank der seitlichen Bohrungen im Gehäuse kann die Baureihe F über die traditione Read more...

Die Baureihe F ist eine ausgezeichnete Lösung für Kunden, die einen Antrieb mit höchster Montageflexibilität benötigen. Dank der seitlichen Bohrungen im Gehäuse kann die Baureihe F über die traditionellen Montagepositionen hinaus auch direkt seitlich an der Maschine montiert werden.Dieser Getriebemotor garantiert höchste Effizienz, Zuverlässigkeit und nahezu geräuschlosen Betrieb. Hohe Drehmomentdichte, ein breiter Übersetzungsbereich und das kompakte Design runden die typischen Eigenschaften der Baureihe F ab. Die Baureihe F kann durch zahlreiche, von Bonfiglioli hergestellte Elektromotoren ergänzt werden. IEC- und Kompakt-Asynchronmotoren (BN-BE-BX/M-ME-MX), Servomotoren (BMD) und Reluktanzmotoren (BSR) können mit der Baureihe F gekoppelt werden. Read less...

|

Key benefits Kostensparende Lösung |

|

| Main options | • Rücklaufsperre • Reduziertes Winkelspiel • Gewindebohrung für seitliche Montage • Drehmomentstütze (mit schwingungsdämpfenden Buchsen) |

| Torque range | 140 ... 14.000 Nm |

| Torque range (IU) | 1,239 … 123,910 in-lb |

| Gear ratios | 6,4 ... 2.099 |

| Certifications | Konformitätserklärung Prüfzertifikat ATEX |

| Transmissible mechanical power | 0,09 ... 123 kW |

| Output | Hohlwelle mit Passfeder - Zwei Abmessungen für jede Größe Schrumpfscheibenpassung ohne Passfeder Aufsteckbare Abtriebsvollwelle als Option Schnellkupplung |

|

Motors Antrieb mit Vollwelle |

|

|

Motors options Thermistoren und Thermostatsensoren |

|

Product Catalogue –Industrial Gearmotors-C-A-F-NEMA

Selection Of Gearboxes- Industrial Gearmotors-C-A-F-S-VF-W

| Designation | i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | n1 [rpm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time | Measurement System | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

F 10 2 19.3

Please continue to proceed with product configuration

Available Variants

|

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19.3 | 2800 | 145.0 | 108.0 | 1.7 | 0.95 | 1100.0 | 1730.0 | 2.7 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22.8 | 500 | 21.9 | 140.0 | 0.34 | 0.95 | 1300.0 | 2800.0 | 0.0 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22.8 | 900 | 39.0 | 140.0 | 0.61 | 0.95 | 1300.0 | 2750.0 | 0.0 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22.8 | 1400 | 61.0 | 140.0 | 0.95 | 0.95 | 1300.0 | 2310.0 | 3.8 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22.8 | 2800 | 123.0 | 119.0 | 1.6 | 0.95 | 1080.0 | 1810.0 | 2.7 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25.8 | 500 | 19.4 | 140.0 | 0.3 | 0.95 | 1300.0 | 2800.0 | 0.0 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25.8 | 900 | 35.0 | 140.0 | 0.54 | 0.95 | 1300.0 | 2800.0 | 0.0 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25.8 | 1400 | 54.0 | 140.0 | 0.84 | 0.95 | 1300.0 | 2430.0 | 3.8 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25.8 | 2800 | 109.0 | 123.0 | 1.5 | 0.95 | 1090.0 | 1890.0 | 2.7 | PARALLEL | Helical-Gear |

Please continue to proceed with product configuration

Available Variants

Cant find what youre looking for? Go to the configurator

| i | n1 [rpm] | n2 [rpm] | Mn2 [Nm] | Pn1 [kW] | ηd [%] | Rn1 [N] | Rn2 [N] | PT [kW] | Layout | Technology | $ | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 29.6 | 500 | 16.9 | 140.0 | 0.26 | 0.95 | 1300.0 | 2800.0 | 0.0 | PARALLEL | Helical-Gear |